Overview

Sewer heat recovery: unlocking urban energy potential

Urban areas face unique challenges in the energy transition: limited space for solar panels or solar thermal systems, shading from dense buildings, and strict preservation regulations often restrict the use of conventional renewable energy sources. Yet, a largely untapped resource lies directly beneath our feet-sewer heat recovery. More use cases for waste heat utilization can be found on the feature page waste heat recovery.

Why sewer heat recovery?

In cities, households, businesses, and industries continuously discharge warm to hot wastewater into the sewer system. This energy is usually lost, flowing unused to treatment plants. Modern sewer heat exchangers now make it possible to efficiently and economically tap into this energy source.

Sewer heat recovery is not only climate-friendly but also already competitive and officially recognized as a renewable energy source. With wastewater temperatures ranging from 10–12°C in winter to 17–20°C in summer, the sewer system provides an attractive and stable temperature level for heating and cooling via a wastewater heat pump.

The existing infrastructure is extensive, with hundreds of thousands of kilometers of sewer pipes. In Germany, for example, estimates suggest that up to 15% of the building sector’s heating demand could be supplied by sewer heat recovery-enough to provide heating for 4 to 12 million people.

Key components of a sewer heat recovery system

A typical sewer heat recovery system consists of three main components:

- Sewer heat exchanger: Extracts heat from the wastewater during winter for heating, or injects excess heat into the wastewater during summer for cooling.

- Wastewater heat pump: Brine-to-water heat pumps are especially suitable, as the brine heated by the sewer heat exchanger can be used directly as a heat source. These systems are highly efficient because wastewater temperatures remain relatively constant year-round.

- Connection and access: The distance between the sewer heat exchanger and the heat pump can be several hundred meters. This distance often determines the economic feasibility of a project.

Why is heat recovery in the sewer network often more efficient than at the treatment plant?

Heat can be recovered either directly from the sewer or at the outflow of the wastewater treatment plant. Both approaches have their advantages, but for decentralized supply in cities, using the sewer network is often more efficient:

- Proximity to heat consumers: Sewers usually run directly beneath or near the buildings to be supplied, minimizing heat losses and piping costs. Treatment plants are typically located on the outskirts, requiring longer transport routes.

- Higher and more stable temperatures: Wastewater in the sewer is generally warmer than after treatment and is constantly replenished. After heat extraction, the temperature recovers quickly, enabling efficient and repeated use within the heating network.

- Flexibility and scalability: Multiple smaller, decentralized systems can be installed in the sewer network, making it easy to adapt to local demand. After each extraction point, the wastewater is replenished and reheated by new inflows and ambient heat.

Sewer heat exchanger: function and installation types

Installing a sewer heat exchanger is a proven technology for waste water heat recovery, with some systems operating for over 15 years. The heat exchangers are integrated directly into the sewer and extract thermal energy without impairing wastewater flow. The recovered heat is then used via a wastewater heat pump for heating and hot water. This is an attractive solution, especially in densely populated areas where other renewable technologies reach their limits.

Installation types include:

- Retrofitted sewer heat exchangers: Installed in existing sewers, requiring coordination with network operators and authorities as they reduce the flow cross-section.

- Factory-integrated heat exchangers in new sewer pipes: Only possible for new builds or complete pipe replacements, with performance determined by proper sizing.

Where are sewer heat exchangers used?

Due to the higher volume of wastewater, sewer heat exchangers are mainly used in public sewer networks and less frequently in industrial sewers. Typical consumers include district heating networks producing district energy and buildings with varying usage profiles, such as commercial properties, schools, hospitals, residential complexes, and large multi-use buildings.

Larger projects are often implemented via energy contracting models, typically by municipal utility companies or regional energy suppliers. Smaller projects, such as single buildings or family homes, are usually self-managed.

Sewer heat recovery is used for heating, cooling, or both. Economically, wastewater heat pump systems are most viable for heating capacities from 50 kW up to 1 MW. For smaller installations, planning and approval costs can outweigh the benefits, though some small systems are already in operation.

Impact of temperature and wastewater flow

Wastewater temperatures fluctuate less than air but still show daily and seasonal variations, especially after rainfall events that cool the wastewater with larger volumes of mixed water. Increased flow during rain can negatively affect heat exchanger performance due to lower temperatures, but it also improves heat transfer and helps clean the exchanger surface.

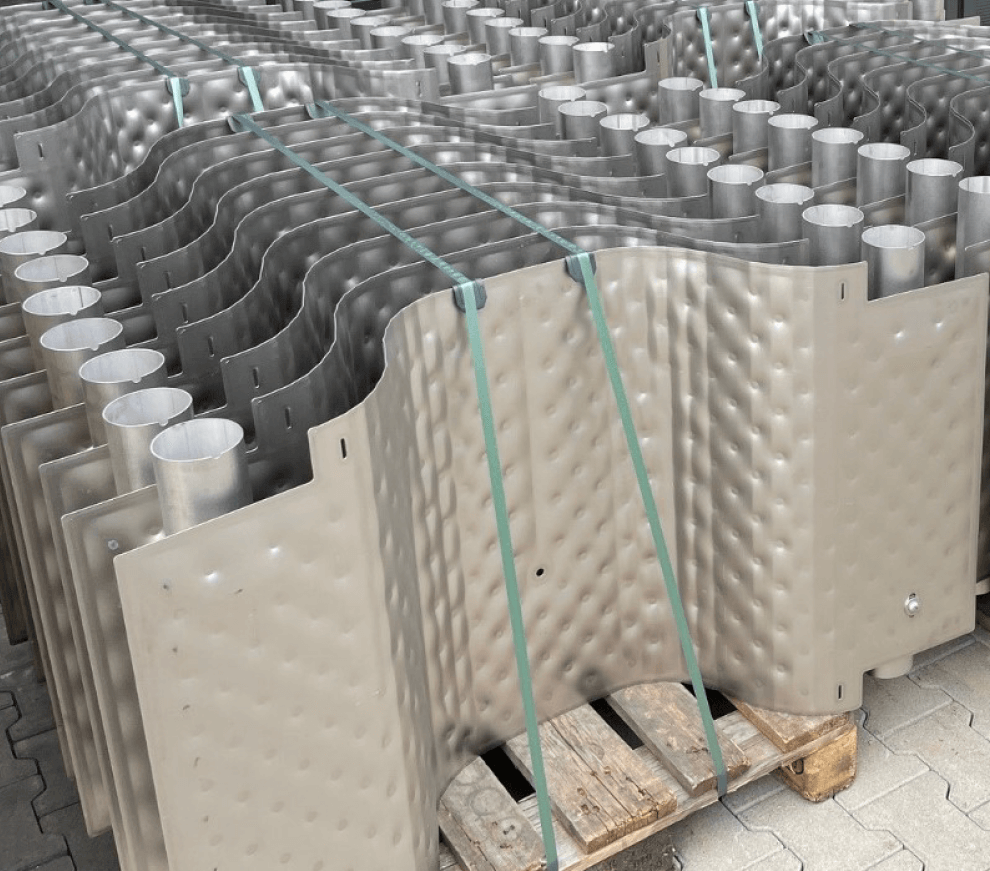

Construction and installation of Uhrig sewer heat exchangers

The system is modular, with each module made of stainless steel plates or pipes with internal flow channels. A partial flow is directed through the modules, and the surface is bathed by the wastewater.

Modules can be rectangular or circular, depending on the sewer cross-section.

Supply and return lines, as well as monitoring conduits, are laid in trenches 0.8 to 1.2 meters deep.

Planning and simulation with Polysun

Planners can use Polysun simulation software to precisely design heat pump systems and district heating networks utilizing sewer heat exchangers. This provides contractors and utilities with a solid planning basis for projects. The sewer heat exchanger component in Polysun allows for detailed simulation, ensuring that return temperatures meet requirements and the optimal system is identified for the required heating and cooling loads.

Polysun offers templates for:

- Brine-to-water heat pump systems with buffer storage, hot water preparation, underfloor heating, and cooling using a sewer heat exchanger.

- Cold local heating networks use wastewater heat with cascaded heat pumps, where the first stage provides an initial temperature lift and a booster heat pump efficiently supplies 60°C hot water.

Conclusion

Sewer heat recovery is a forward-thinking solution for urban energy transition. With innovative sewer heat exchangers, intelligent simulation and planning, and proven systems, cities, and utilities can make a significant contribution to climate protection while securing their heat supply. Polysun simulation provides a reliable basis for subsidy applications and the development of funding schemes across Europe via a wastewater heat pump for heating and hot water. This is especially attractive in densely populated areas where other renewable technologies reach their limits.

What are the requirements for sewer heat recovery?

When planning to use heat from public sewers, the following requirements must be considered:

– Sufficient thermal potential in the sewer

– Suitable dimensions and cross-section of the sewer

– Any retrofit installation of sewer heat exchanger elements in existing sewers must be reported to the relevant authorities

– Sewer inspection and visual checks must be possible

– The temperature of the wastewater at the inlet to the treatment plant (usually not relevant in practice due to partial flows)

– Feasibility based on local site conditions

– Feasibility for cooling applications (if required)

Does a biofilm form on the sewer heat exchanger?

Yes, a biofilm forms on the sewer heat exchanger, but this does not cause any problems. The presence of a biofilm is taken into account during system design, meaning that the sewer heat exchanger is oversized accordingly to compensate for any reduction in heat transfer.

Is there a standard value for heat output per meter?

No, there is no standard value for output per meter for sewer heat exchangers. The heat extraction per meter depends on many factors, such as:

– The circumference of the sewer: the wider the sewer, the larger the sewer heat exchanger and the higher the heat extraction per linear meter

– The heat transfer from the wastewater and the water level in the sewer

– The temperature difference between the wastewater and the heat transfer medium

A good rule of thumb is a heat extraction of about 2 kW per square meter of sewer heat exchanger surface.

What should be considered regarding maintenance of sewer heat exchangers, and who is responsible?

Sewer heat exchangers are low-maintenance. In practice, inspections are often only necessary after 20 years or not at all. Most projects do not require maintenance after commissioning. The system operator is responsible for maintenance. The sewer network operator carries out regular inspections and cleaning of the sewer. Cleaning is usually performed annually in frequently cleaned sewers and every five years in less frequently cleaned ones. The performance of the sewer heat exchanger can be monitored by tracking the supply and return temperatures.

Is there a minimum sewer diameter for installing a sewer heat exchanger?

Yes, there is a minimum sewer diameter for installing sewer heat exchangers. The minimum size is determined by the smallest cross-section that allows safe access for installation. Installation in smaller sewers is possible using insertion methods, but this is rarely economical and can increase complexity for future expansion or maintenance.

Does installing a sewer heat exchanger affect microorganisms in the wastewater treatment plant?

The impact of a sewer heat exchanger installed at an average distance of 10 km from the treatment plant on the influent temperature is negligible, as only partial flows are affected. Treatment plants are designed to operate with influent temperatures below 12°C, even in winter. According to established best practices, a temperature drop of less than 0.5°C at the treatment plant inlet due to heat extraction is considered insignificant.

What is the minimum flow rate required for planning a sewer heat exchanger?

As a rule of thumb, the minimum flow rate in the sewer should be at least 10 liters per second for the effective operation of a sewer heat exchanger.

Can the sewer become blocked by the heat exchanger?

Modern sewer heat exchanger systems, such as the Uhrig Therm-Liner, are designed to prevent blockages. A ramp in front of the first module ensures a smooth transition and prevents deposits or obstructions.

Can the sewer heat exchanger be installed while the sewer is in operation?

Yes, the sewer heat exchanger can be installed without shutting down the sewer. A typical installation takes 2 to 6 weeks. During this period, a bypass is created for the dry weather flow-either within the sewer, using external pumps, or by temporary diversion. During heavy rain, the site is temporarily cleared and the system is overflowed.

Which heat transfer fluid is used: water-glycol or water?

Both are used. Water is preferred for higher heat transfer efficiency at higher wastewater temperatures. At lower temperatures, water-glycol mixtures are used to prevent freezing. Water-ethanol mixtures can also be used.

Is sewer heat recovery often combined with other heat sources in local heating networks?

Yes, this is common practice. Sewer heat recovery is often combined with other sources such as geothermal energy, traditional gas boilers, or other renewable heat sources.

Is the sewer heat exchanger component available in Polysun?

Yes, the sewer heat exchanger component is available in Polysun as of version 2025.4.

By how many degrees Celsius can the wastewater be heated or cooled?

This value varies depending on the local sewer network (city). Typically, the allowable change is +3°C or -3°C, but specific limits are set by the local authorities.

What terminology is used for the design of a wastewater heat exchanger in the sewer?

Engineers search for different terms internationally, depending on the national language and the technical context. Here are some examples of relevant search and technical terms:

– German: Abwasserwärmetauscher Kanal, Wärmegewinnung aus Abwasserkanal, Auslegung Abwasserwärmetauscher, Kanalwärmetauscher

Englisch: sewer heat exchanger, wastewater heat exchanger, sewer heat recovery, sizing wastewater heat exchanger, sewer heat recovery system design

– French: échangeur de chaleur sur réseau d’égouts, récupération de chaleur des eaux usées, dimensionnement échangeur de chaleur eaux usées

– Italian: scambiatore di calore per fognatura, recupero calore dalle acque reflue, dimensionamento scambiatore calore fognatura

– Dutch: rioolwarmtewisselaar, warmtewinning uit rioolwater, ontwerp rioolwarmtewisselaar