Overview

Buffer tanks in parallel or in series: How to achieve planning reliability and cost-effectiveness

When planning larger heat pump systems – for example in hotels, schools, kindergartens, industrial buildings, or multi-family houses – the arrangement of the buffer tanks and the buffer tank sizing is of crucial importance. The choice of connecting the buffer tank parallel or in series directly impacts the efficiency, flexibility, hydraulic stability, and ease of maintenance of the system. This technical article explains the differences, application areas, and design principles of both variants: buffer tank parallel or in series. In addition, practical examples illustrate how larger systems with multiple buffer tanks can be optimized and reliably planned.

Terminology and Table of Content

In practice, two different areas of application are distinguished when referring to buffer tanks connected in parallel or in series. One concerns the arrangement of multiple buffer tanks in relation to each other. The other relates to the hydraulic integration of a single buffer tank into the heating circuit—again either in parallel or in series. The table of contents below allows you to navigate directly to the section relevant to your application.

- Terminology and Table of Content

- Area of application 1: When are buffer tanks connected in series?

- When are buffer tanks connected in parallel?

- Description of use cases with buffer tanks in series connection and their diagram

- Description of use cases with parallel buffer tanks and their diagram

- Area of application 2: hydraulic integration of the buffer tank – parallel, branch, or series

- Conclusion

- FAQ

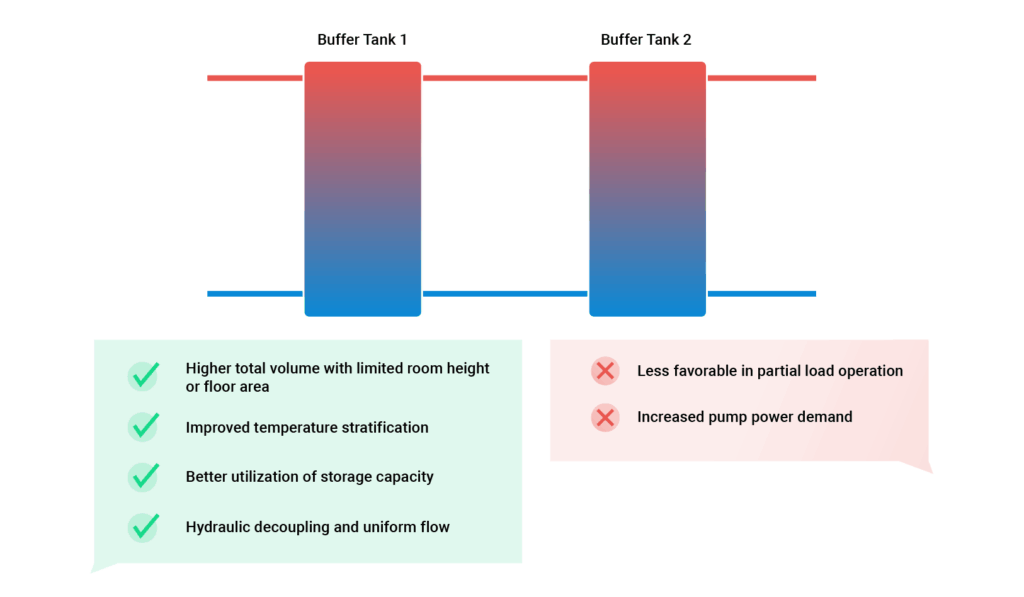

Area of application 1: When are buffer tanks connected in series?

The series connection (serial integration) of buffer tanks is suitable for systems that require a continuous volume flow and a linear, zoned temperature stratification. In this configuration, the buffer tank is fully integrated into the main heating circuit, so that the heating water always flows completely through the storage tank before returning to the heat pump or being distributed to the heating circuits.

In practice, buffer tanks are connected in series in larger systems for various reasons:

1. Larger total volume with limited room height or floor space

- A single buffer tank with a very large volume is structurally difficult to transport and in some cases cannot even be brought into the installation room. In contrast, several smaller tanks are easier to handle and install.

2. Improved temperature stratification

- In a series connection, the heating or cooling medium flows through the buffer tanks one after another. As a result, the temperature stratification in each tank remains more stable, since each tank only has to represent part of the temperature difference. With parallel-connected buffer tanks, however, the entire temperature spread must be covered. The water therefore flows more calmly through each individual tank, leading to less mixing of warm and cold water and maintaining stratification for a longer period.

3. Higher utilization of storage capacity

- With series connection, one storage tank is first fully “used up” before the next one is actively charged or discharged. This prevents mixing zones and ensures a higher amount of usable energy.

4. Hydraulic decoupling and uniform flow

- Arranging several storage tanks in series ensures a constant flow through all buffer tanks. This prevents short circuits in the flow path, which can occur with parallel connection.

However, the serial integration of a buffer tank also comes with certain disadvantages. It has a particularly unfavorable effect in partial load operation. When the heating demand is low, for example during transitional periods, an unnecessarily large amount of heating water flows through the buffer tank. This leads to significant efficiency losses. In addition, routing the entire heating circuit through the tank increases the hydraulic resistance. As a result, the circulation pump has to deliver more power, which in turn increases electricity consumption.

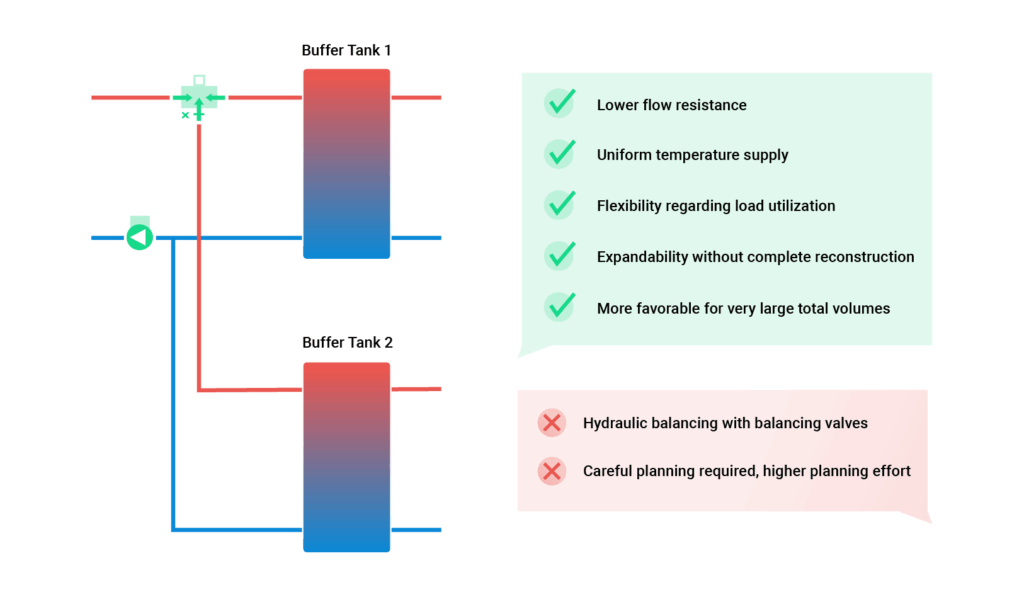

When are buffer tanks connected in parallel?

Parallel connection (also known as hydraulic decoupling) is standard in larger heat pump systems with multiple heating circuits, variable volume flow, or when supplying different consumers simultaneously (e.g., heating, air heaters, hot water preparation).

In practice, buffer tanks are connected in parallel in larger systems for various reasons:

1. Lower flow resistance

- When buffer tanks are connected in parallel, the total volume flow is divided among several tanks, in contrast to a series connection. As a result, only a partial flow with a lower flow velocity flows in each tank, which leads to lower pressure loss in the overall system. This is particularly advantageous in very large systems with high flow rates, such as district heating centers or large heating systems.

2. Uniform temperature supply

- Since each storage tank is connected directly to the flow and return lines, all storage tanks are charged and discharged simultaneously. This is advantageous if the system design requires the same temperature level in all storage tanks.

3. Flexibility in terms of utilization

- In partial or full load operation, it is possible to disconnect individual storage tanks from the network via shut-off valves (e.g., for maintenance work or when less storage volume is required). This reduces losses caused by storage tanks being kept warm unnecessarily.

4. Expandability without complete conversion

- New buffer tanks can be easily connected in parallel to the flow and return lines without having to make major changes to the existing hydraulics.

5. More cost-effective for very large total volumes

- Very large individual storage tanks are expensive and difficult to transport. Several smaller storage tanks, on the other hand, are often more cost-effective to purchase, install, and transport.

The planning and implementation of parallel-connected buffer tanks is more complex. In this case, the flow distribution must be carefully balanced hydraulically; otherwise, one tank may charge more than the others. Likewise, temperature stratification in the tanks can be lost more quickly if the volume flow is high or distributed unevenly.

The following sections present the most common application cases in which HVAC planners and engineers design buffer tanks either parallel or in series.

Description of use cases with buffer tanks in series connection and their diagram

Buffer tanks are connected in series in the following application areas, for example:

- Energy-efficient renovation of multi-family houses with limited room height

- Schools with constant, linear energy demand

- Systems with only one heating circuit and few dynamic loads.

- Industrial applications with continuous process heat supply without large load fluctuations.

The following sections present common application cases in which buffer tanks are planned either parallel or in series.

Energy-efficient renovation of multi-family house with limited ceiling height

In this energy renovation of a multi-family house, three buffer tanks are connected in series due to the limited room height. Heat generation is provided by a PVT system, a heat pump, and a geothermal probe. During summer, the hybrid solar panels charges the buffer tanks with heat while simultaneously regenerating the geothermal probe. Depending on the buffer tank supply temperature, charging takes place through different inlets. Discharging occurs through the corresponding outlet, depending on the required supply temperature for domestic hot water and underfloor heating.

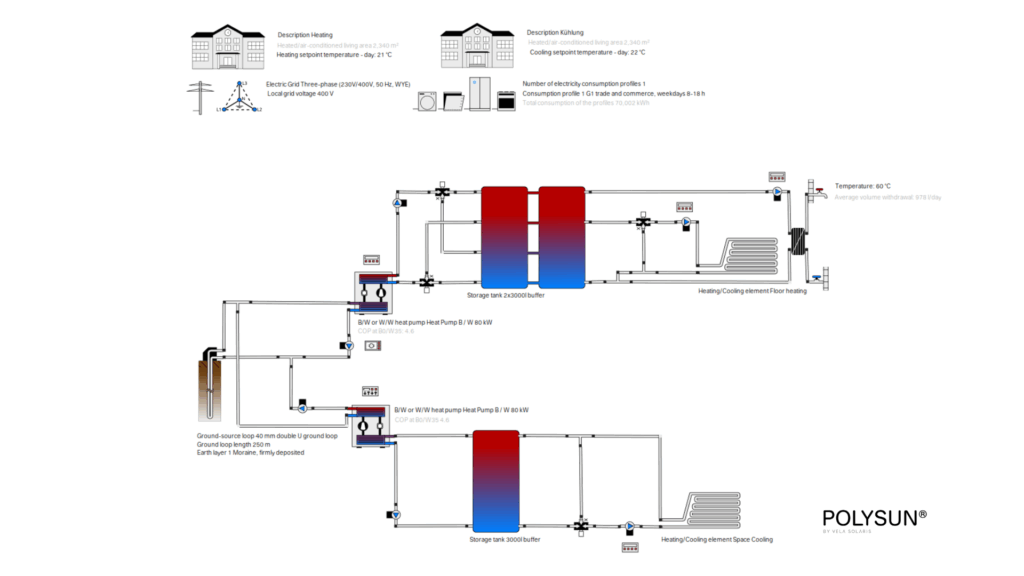

School with fresh water station and cooling system

Geothermal energy serves as the energy source, which is elevated by the heat pump to different temperature levels for underfloor heating and domestic hot water supply. Depending on the required temperature, the buffer tank is charged at the corresponding inlet. The cooling circuit is shown separately: the lower circuit is used for active cooling. In summer, the cooling element extracts heat from the building and stores it in the borehole, thereby regenerating it.

Description of use cases with parallel buffer tanks and their diagram

Buffer tank connected in Tichelmann style

Buffer tanks can be integrated according to the Tichelmann system. Two buffer tanks connected in parallel are arranged following the Tichelmann principle in such a way that the first tank is closer to the heat source on the supply line and the second tank is closer on the return line, resulting in hydraulically equal flow path lengths for both tanks.

This leads to identical pressure losses in both buffer tank branches, allowing the volume flows to distribute evenly without the need for additional hydraulic balancing.

In simulation models, this is represented by identical pipe parameters and symmetrical connection conditions for both buffer tanks.

The Tichelmann principle ensures that all parallel-connected consumers (or buffer tanks) have the same hydraulic resistance. In simulation terms, this means:

identical pipe lengths (supply + return), equal pipe diameters, equal pressure losses and therefore equal volume flows without complex hydraulic balancing.

For a detailed representation and simulation of the Tichelmann system, pressure losses and fittings must be modeled in detail. In energy and building simulation software, hydraulics are usually simplified and calculations focus on energy performance. Software such as Polysun or EnergyPlus distributes volume flows automatically or in an idealized manner.

This level of modeling accuracy is sufficient for planning purposes in the vast majority of practical applications. In reality, implementing the Tichelmann system is often more a matter of correct construction and execution, long pipe runs, or the available space.

In practice, the term “parallel buffer tanks” is not used exclusively for Tichelmann arrangements. The following section describes common real-world examples and illustrates typical parallel buffer tank configurations in schematic form.

Examples include:

- Newly constructed multi-family houses with high heating requirements

- Office buildings or hotels with highly fluctuating energy requirements and peak load demands

- Local and district heating systems with high volume flows that need to be covered evenly from several storage tanks

- Industrial applications with variable loads that require redundancy and flexibility in storage management.

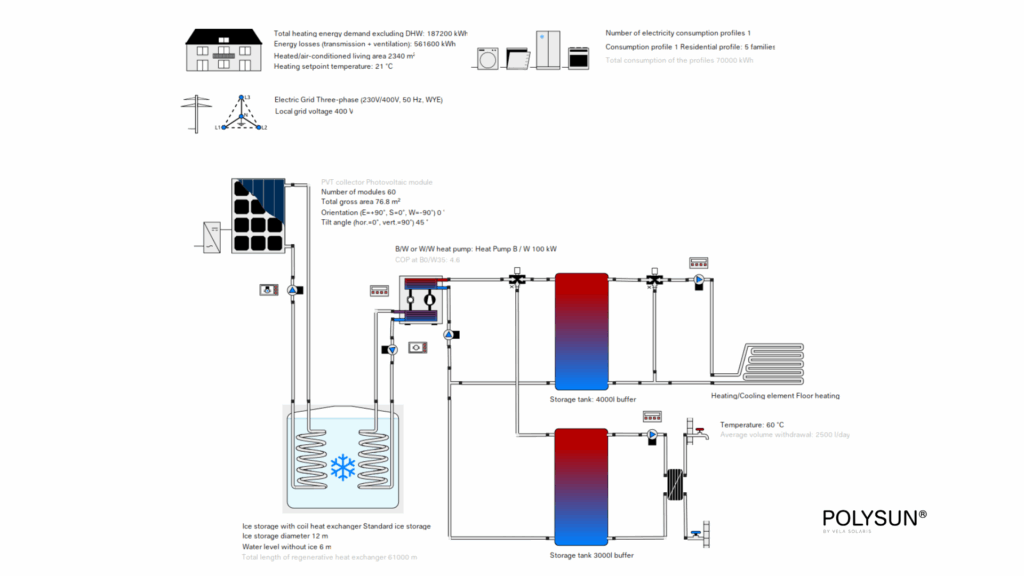

New multi-family house, neighborhood development or office complex with ice storage

This system, which can be implemented for example in a multi-family house, a neighborhood development, or an office complex, uses an ice storage as the central energy source. The ice storage is able to store large amounts of heat in a compact volume and can be operated reliably thanks to continuous regeneration by the PVT modules. The energy stored in the ice storage is utilized by the heat pump to supply both space heating and domestic hot water.

To meet the different requirements of these two applications, separate buffer tanks are installed: one for the underfloor heating circuit, which operates with low supply temperatures and thereby supports the efficient operation of the heat pump, and another for domestic hot water, which requires significantly higher temperatures to ensure hygienic standards. As a result, the heat pump does not have to constantly switch between different temperature levels but can charge the two buffer tanks in a targeted manner.

For the ice storage, this means a more balanced and predictable load, since the buffer tanks absorb short-term peak demands. This facilitates the regeneration of the ice storage, increases its lifetime, and enhances the overall efficiency of the system.

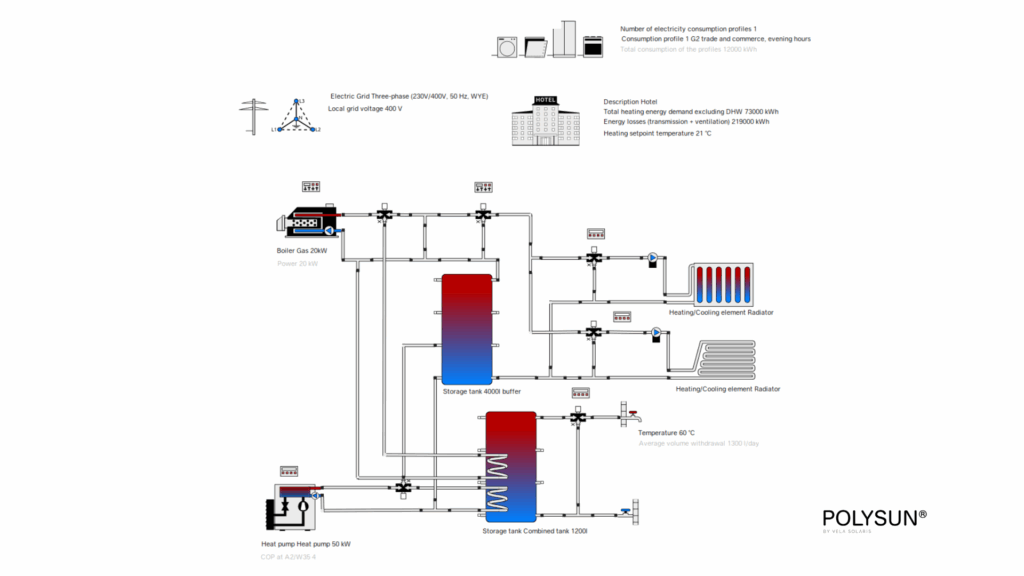

Hotel with bivalent system

A hotel with a hybrid heat pump system uses a combination of a heat pump and a gas boiler, which is particularly useful when renovating existing buildings. These often have both modern underfloor heating systems with low supply temperatures and older heating circuits with radiators that require higher temperatures. To efficiently meet these different requirements, two separate buffer tanks are installed: one buffer tank supplies the heating circuits and provides the required supply temperature for both underfloor heating and radiators, while the second buffer tank is used for domestic hot water preparation and is operated at a higher temperature level.

Both the heat pump and the gas boiler are connected to both buffer tanks. The heat pump covers the base load, preferably operating with the low temperatures of the underfloor heating, thereby achieving a particularly high efficiency. When demand increases, for example in peak load situations, the gas boiler is switched on. It can flexibly charge both buffer tanks, ensuring both domestic hot water supply and heating for the radiators. With this division of tasks, the buffer tanks take on an important buffering and decoupling role: they smooth out load fluctuations, enable the simultaneous operation of heating circuits with different temperature levels, and prevent the heat pump and gas boiler from constantly switching between operating modes. The result is reliable, efficient, and demand-oriented operation of the entire hybrid system.

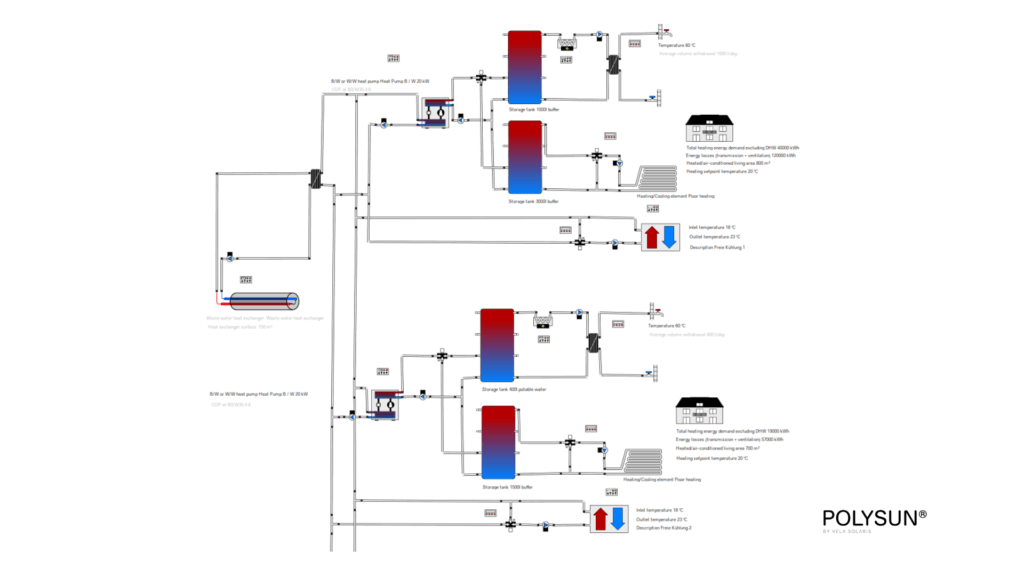

Low temperature district heating system with wastewater heat exchanger and free cooling

In a low temperature district heating system with sewer heat recovery, the source energy is provided centrally. However, each connected multi-family house has its own heat pump, which raises the heat available in the network to the required temperature level. Within each building, two buffer tanks ensure the efficient use of this energy: one buffer tank covers the heating circuit, while the second is used for domestic hot water preparation.

The buffer tanks act as intermediate storage and provide hydraulic decoupling between the low-temperature district heating system and the individual heating and hot water systems of the apartments. This allows the heat pump to operate steadily, without having to react directly to peak loads in the heating circuit. In summer, the system is also used for free cooling. Excess heat from the buildings is fed back into the district heating system and discharged via the central wastewater heat exchanger, thereby cooling the buildings.

Area of application 2: hydraulic integration of the buffer tank – parallel, branch, or series

A buffer tank in a heat pump system can be integrated into the hydraulic circuit in different ways. An overview of the different types of buffer tank integration can be found in our article “buffer tank heat pump”. How the buffer tank and heat pump are hydraulically connected has a significant impact on efficiency (COP), switching behaviour, return temperatures and the controllability of the system. Below, three common integration methods — parallel, branch, and series — are described and classified.

Connect the buffer tank as a hydraulic decoupler in parallel

To integrate a buffer tank in parallel, the buffer tank must be connected to both the supply and return lines of the heating circuit. This is also referred to as a 4-connection buffer tank arrangement. In this configuration, the heat pump and the heat sink (heating circuits) are hydraulically decoupled; both sides have their own circulation pumps and distinct volume flows. The buffer tank acts as a hydraulic decoupler (hydraulic separator).

Different volume flows between the primary side (heat pump) and secondary side (heating circuit) inevitably lead to mixing within the buffer tank. This can result in: possible increase in return temperature to the heat pump, reduced COP (often by several ten percent), increased switching tendencies due to lack of a genuine heat sink and additional pump losses.

This type of integration is energetically critical, especially for modulating heat pumps with load-dependent volume flows. It can work in special cases (e.g. complex multi-consumer systems or older installations with unclear hydraulics), but it is generally not the preferred solution for modern, efficiently designed heat pump systems.

Tee connection- connect buffer tank with a branch connection off the main heating circuit

In a branch integration, the buffer tank is connected sideways to the main volume flow between the heat pump and the heating circuit. Under normal operation, the main volume flow circulates directly between the heat pump and the heat sink; the buffer tank is only charged or discharged when there are volume flow deviations or temporary excess power.

Here the buffer tank does not act as a flow element but as a “breathing” tank. It stores energy when the heat source delivers more power than the heat sink consumes, and delivers energy when there is short-term increased demand — while largely leaving the main flow unaffected.

Effects and benefits include:

- low mixing,

- no systematic rise in return temperature,

- good COP values,

- reduced switching frequency.

Branch integration is often a good compromise when a buffer tank is required (e.g. for defrosting energy, minimum volume or hydraulic calming) without significantly worsening the heat pump’s efficiency.

Connect the buffer tank in series/in line with the heating circuit

In the series integration, the buffer tank is fully integrated into the main volume flow. The entire volume flow of the heat pump first flows through the buffer tank and then through the heat sink – or vice versa depending on the concept. Here, the buffer tank becomes a true thermal mass within the system. There is a single shared volume flow for heat generator and heat sink, and flow conflicts, short circuits or mixing processes do not occur.

Effects and benefits include:

- defined, low return temperatures,

- maximum heat pump efficiency,

- very stable operating behaviour,

- significantly reduced switching.

Today, series integration is considered hydraulically and energetically preferable, particularly for modulating heat pumps in single and multi-family homes. It requires that the buffer tank is correctly sized and optimized for stratification.

Conclusion

When sizing larger heat pump systems and sizing district heating systems, the correct arrangement of buffer tanks is crucial for the cost and operational reliability of the heat pump system. Connecting multiple hot water tanks in series is particularly suitable for applications with linear volume flow and stable temperature stratification, as it ensures greater utilization of storage capacity and an even flow. Buffer tanks connected in parallel, on the other hand, offer advantages for variable loads and multiple heating circuits, as they provide hydraulic decoupling, reduce flow resistance, and enable flexible usability and easy expansion. The choice between parallel and series buffer tanks therefore depends largely on the specific requirements of the system, the heat demand, and the hydraulics. Both types of connection offer important advantages and should be planned according to the situation to ensure optimum performance and reliable operation.

FAQ

What dimensioning principles for buffer tanks are relevant according to VDI 4645 and DIN EN 15450?

The buffer tank sizing for heat pump systems is based on the specifications of VDI 4645 and DIN EN 15450. According to VDI 4645, a buffer tank should be designed with approximately 20 liters per kilowatt of heat pump capacity. DIN EN 15450, on the other hand, recommends a range of 12 to 35 liters per kilowatt, depending on the respective application and operating conditions. Specific boundary conditions apply to large systems, which take into account the different load profiles and types of use. In hotels, a storage volume of 25 to 40 liters per kilowatt is recommended in order to compensate for the highly fluctuating load profiles and typical hot water demand peaks. Schools and kindergartens, on the other hand, require smaller storage tanks of 15 to 25 liters per kilowatt, as the usage times are clearly defined and only low loads occur at night. In industrial buildings, the recommended range is 20 to 35 liters per kilowatt, although the requirements here depend heavily on the respective processes. For multi-family houses, buffer tanks are dimensioned at 20 to 30 liters per kilowatt.

How does the storage capacity affect the annual performance factor (APF) of the heat pump?

The storage capacity (also known as the storage factor) indicates how large the heat storage tank is in relation to the heating load or the output of the heat pump. It influences the operation of the heat pump and thus indirectly affects the annual performance factor (APF), i.e. the average performance factor over the year. An appropriate storage volume ensures that the heat pump operates closer to its optimum operating points, resulting in a higher APF. However, if the storage tank is too large, additional storage losses occur due to heat dissipation to the environment, which reduces the APF again. If, on the other hand, the storage tank is too small, more frequent cycles occur, which also results in a reduction in the APF.

How is hydraulic balancing ensured when there are multiple storage tanks?

In systems with multiple hot water tanks, hydraulic balancing is necessary to ensure uniform charging and discharging and to prevent flow short circuits and undesirable temperature differences. This is primarily achieved through suitable hydraulic interconnection and coordinated control. If storage tanks are connected in parallel, it is important that they are all connected via identical pipe routes and cross-sections, as specified by the Tichelmann principle. This ensures that the flow resistance remains the same in each storage tank and the volume flows are distributed evenly. In addition, line control valves or dynamic flow controllers can be used to adjust the flow rate as required. The control system uses temperature sensors to monitor the status of the storage tanks and controls pumps or valves to ensure uniform loading and unloading. In many cases, a priority storage tank is defined, which is loaded first before other storage tanks are activated. While the symmetrical connection according to Tichelmann is usually sufficient for smaller systems, in larger systems with several storage tanks, the balancing is often additionally supported by automatic control valves. This is due to the fact that equal pipe lengths are hardly feasible in such systems.

How can storage tanks be used for different temperature zones (e.g., heating, hot water)?

Storage tanks can be designed and connected in such a way that they provide different temperature zones for heating and hot water. This is usually achieved by using a stratified arrangement in the storage tank or by using multiple hot water tanks, each designed for a specific temperature. In a stratified storage tank, the natural density of the water separates the different temperature ranges from each other. Hot water for domestic hot water production collects in the upper section. The middle section contains heating water at moderate temperatures and the lower section contains colder water that flows back into the heat pump.

You can find out more about stratified storage tanks here. To ensure that the stratification remains stable, a suitable inflow technology is required to prevent turbulence. Alternatively, separate storage tanks can be used for the individual temperature zones, which are then connected to each other via a hydraulic control system. Although this increases the installation costs, it enables targeted optimization of the respective temperature ranges and reduces mutual interference.

Do check valves or motorized shut-off valves need to be installed to prevent unwanted flow?

In systems with multiple hot water tanks or complex hydraulics, it is usually necessary to install check valves or motorized shut-off valves to prevent unwanted flow. Without these devices, undesirable circulation can occur, for example, when storage tanks with different temperature zones are hydraulically connected or when pumps allow heat transfer during shutdown. Check valves prevent the medium from flowing back and ensure that the flow only occurs in the desired direction. Motorized shut-off valves also offer the option of opening or closing pipes in a targeted manner, thus allowing flexible control of operation. This is particularly useful if certain storage tanks are only to be connected temporarily or if a clear separation of individual operating modes – such as heating, cooling, or hot water preparation – is required. While check valves are a simple and cost-effective solution, motorized shut-off valves enable more precise control and are therefore often used in larger or more complex systems. This ensures that the system operates efficiently and prevents energy losses due to uncontrolled flows.