Waste Heat Recovery – Technologies, Applications and Planning with System Simulation

Waste heat recovery is becoming increasingly important for companies, energy utilities and building planners. By recovering waste heat, you can reduce operating costs, cut CO₂ emissions and relieve load on heat networks. However, different temperature levels, time-based profiles and load characteristics make implementation challenging. Precise planning with simulation is therefore essential to integrate waste heat economically and reliably into energy systems.

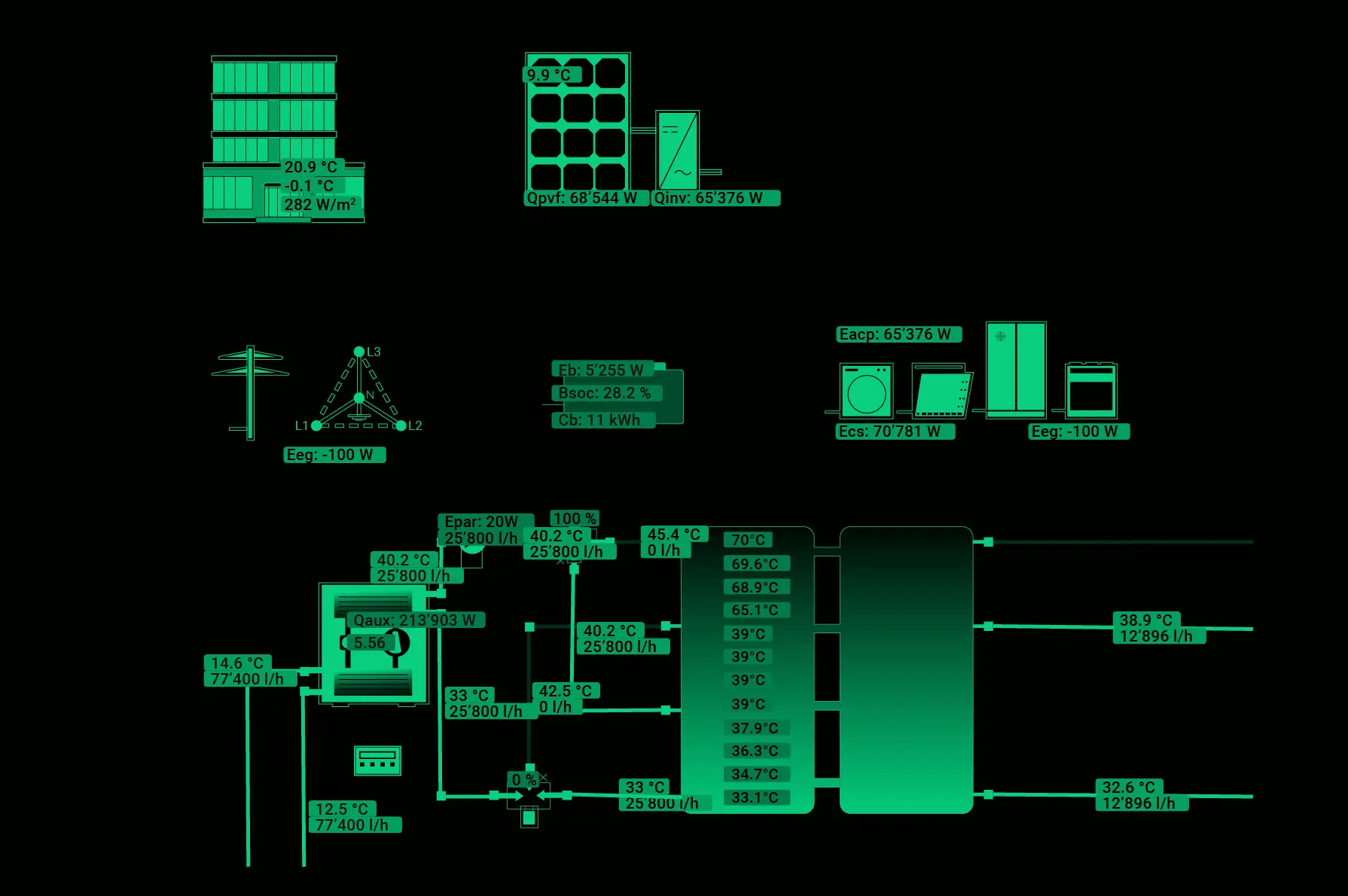

Polysun enables detailed analysis of heat flows, load profiles and overall system behaviour, allowing planners to design sustainable and optimally sized energy systems using waste heat recovery.

Waste Heat Recovery Technologies

Direct Waste Heat Utilisation with Heat Exchangers and Thermal Storage

For many applications, the available waste heat is at a temperature that can be used directly. Heat exchangers transfer the heat directly into district heating or local heat networks, particularly where higher supply temperatures are available. Thermal storage systems can be added to decouple production and demand over time, which is especially useful in industrial processes with fluctuating output or for seasonal storage.

Indirect Waste Heat Recovery with Heat Pumps

When the waste heat is too cold or its temperature level does not match the demand, heat pumps are used to raise the temperature. A waste heat recovery heat pump makes even low-temperature sources usable — for example, waste water, ventilation exhaust air, industrial process heat or data centre waste heat. Indirect utilisation therefore opens up heat sources that would otherwise be uneconomic or technically unusable.

Typical Applications for Delivering Usable Waste Heat

In practice, large projects often combine multiple energy sources. Diverse producers, temperature levels and load profiles must be matched to find the most cost-effective solution. The following typical waste heat recovery applications are frequently planned:

Building Waste Heat – Free and Active Cooling

Modern buildings generate increasing cooling demand — and valuable waste heat. This heat can be reused through free cooling or via refrigeration systems. Typical concepts include returning the geothermal fields for regeneration or integrating it via heat pumps into local heat networks. Buildings with cooling demand can thus serve as decentralized waste heat sources.

Waste Water Heat for District and Local Heat Networks

Waste water offers relatively stable temperatures and is an attractive source for heat networks. By using waste water heat exchangers, temperature fluctuations in sewer systems can be stabilized and valuable energy recovered for network use. Combined with heat pumps, it’s possible to achieve the desired network supply temperatures. See also the separate waste water heat exchanger feature page.

Data Centres – Continuous Waste Heat as an Energy Source

Data centres generate continuous waste heat at relatively stable temperature levels (typically ~25 °C–40 °C), making them ideal for utilisation in heat networks. The challenge is balancing IT cooling, heat pump operation and network conditions. Simulation helps ensure that temperature lifts, return temperatures and network dynamics are properly considered.

Industrial Waste Heat Recovery

Industrial processes often release high temperature levels that can be directly used or elevated with heat pumps. Typical questions include how best to recover the waste heat and how to supply process heat efficiently. Simulation tools help evaluate both technical feasibility and economic performance.

Exhaust Air and Flue Gas Recovery

Systems such as waste-to-energy plants and incinerators also produce significant waste heat that can be fed into heat networks.

What Value Does System Simulation Bring to Waste Heat Recovery?

Heat Pump Based Waste Heat Recovery

Using a heat pump for waste heat recovery is one of the most flexible and efficient ways to elevate low-temperature heat (from waste water, industrial processes, ventilation exhaust or data centres) into useful heating energy. The stable source temperature enables high efficiencies and supports decarbonisation. With dynamic simulation, Polysun calculates realistic COP (Coefficient of Performance) and annual performance factors (JAZ), helping you dimension and control waste heat recovery systems precisely and reliably.

FAQ

Can the available waste heat technically be integrated into our district or local heating network?

Yes, but this strongly depends on three factors: temperature level, heat output, and temporal availability of the waste heat source. Many sources — such as data centres, industrial processes, or wastewater — provide heat at relatively low temperatures. System simulation helps determine whether the waste heat can be fed directly into the network or if a heat pump or temperature boosting is required.

Municipal utilities and energy contractors gain confidence in the technical feasibility of the project and how to achieve optimal hydraulic integration.

How does waste heat from a data centre affect our existing heating network?

Data centres deliver a very constant but low-temperature base load (typically 25–40 °C). Not every network can utilise these temperatures efficiently. Simulations allow realistic calculation of temperature lifts, required heat pump capacity, COP/annual performance factor (JAZ), and the impact on supply and return temperatures.

By modelling different scenarios — with and without storage or boosting — the simulation shows how the waste heat can be optimally used, or if adjustments in network operation are necessary.

Which storage or network components are needed to reliably utilise fluctuating waste heat (e.g., from industrial processes)?

Volatile waste heat sources — such as batch processes, drying, exhaust air, or seasonal sources like ice storage — are often only partially utilisable without storage. Simulation calculates the optimal storage size, temperature range, and storage type (short-term or seasonal) to maximise usable heat.

This helps municipal utilities avoid over-sizing and provides data-driven recommendations for buffer tanks, network pumps, and control strategies.

How reliable is the waste heat source, and how does its availability affect contracts and economic feasibility?

Waste heat sources vary in reliability: data centres are usually very stable, while industrial processes or biogas systems can fluctuate significantly. Simulations provide annual operating hours, load profiles, failure scenarios, and seasonal variations. These values are crucial for feed-in contracts, investment decisions, and sizing of supplementary heat generation (e.g., peak boilers).

Energy contractors use this data to quantify risks, define guarantees, and realistically assess economic models.

What COP/annual performance factors (JAZ) and operating costs can we expect from a waste heat heat pump?

The efficiency of a waste heat heat pump directly depends on source temperature, load profiles, partial-load behaviour, and network temperatures. Simulation models these factors hour by hour and delivers realistic COP/JAZ and electricity consumption — much more precise than static calculations.

This allows a better assessment of operating costs, the economic feasibility of heat injection, and optimal system sizing. Municipal utilities can use this data to confidently decide whether a waste heat project is economically viable in the long term.