Models

There are two different ice storage models available in Polysun. The “Coil Heat Exchanger Model” uses an empirical Enthalpy-Temperature-function. This function represents the decrease of the source temperature due to ice on the heat exchangers. While ice is growing, the heat transfer value of the heat exchanger decreases, forcing the system to go to lower temperatures in order to extract the same power from the ice storage. The function is fixed to a specific heat exchanger geometry and should be derived from measured performance data of the ice storage. Different functions for different geometries can be stored in the catalogue. As a default, the function for a Viessmann-Isocal ice storage is provided. The dimensions and the insulation of the storage tank can be parametrized as well as the material properties and the length of the heat exchanger coils.

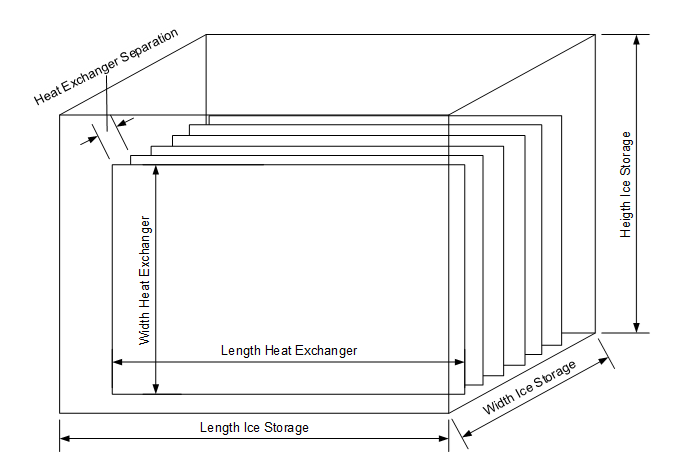

The new model “Ice Storage Plate Heat Exchanger” was designed to simulate ice storages with plate heat exchangers. The heat exchanger material and geometry as well as the distance between heat exchangers in the ice storage can be parametrized. Therefore, the model can be used to test and simulate new ice storage configurations ad hoc without the need of providing experimental data. In addition, in comparison to the Coil Heat Exchanger Model, the Plate Heat Exchanger Model accounts for measureable differences in the heat transfer properties between icing and melting making it precise in reproducing both behaviors.

The ice storage is in a thermal exchange with its surroundings – the ground or the basement – and with the heat exchangers connected to it that link the ice storage to the other components. The connection to the ground is modeled with an earth layer that connects the ice storage to the temperature of the undisturbed earth. In addition, the location of the ice storage can be changed to cellar with a fixed surrounding temperature only in the Plate Heat Exchanger Model.

Polysun supports cylindrical and cuboid shapes of ice storages. For a realistic simulation, a sufficiently long preliminary simulation time should be set, for example 180 days.