Solar Thermal Collectors

The above mentioned irradiation values naturally cannot be entirely utilized by a collector. There are various factors which contribute to cause one part of the energy not to be transmitted to the heat transfer fluid.

- The partial reflection on the cover glass (approx. 8%), except for uncovered collectors

- The partial absorption by the collector, depending on the coating: minus 4-10 %

- The incomplete cooling of the absorber, the so-called factor F’: minus 3-10 %

- The emission of heat by thermal radiation, depending on the coating and the temperature

- The loss of heat by means of thermal conduction and convection, losses depending on temperature

The efficiency of a collector greatly depends on the difference between the average temperature of the collector and the external temperature. If this difference is substantial (i.e. 80°C), there are great losses because of thermal radiation and convection. In case of small temperature differences, the efficiency can reach up to approx. 90%. When the temperature of the collector, due to cold fluid, is less than the surrounding ambient temperature, an efficiency could result even “greater than 100%”. In this case the heat transfer fluid becomes heated not only by the sun, but also by the heat from the surrounding environment.

There are three different types of collectors. The most suitable one depends on user needs.

Unglazed collectors: uncovered flat-plate collector type. Unglazed collectors are ideal for heating pools and for certain uses of pre-heating hot water. In regions where strong winds prevail, there are greater convective losses. On the other hand unglazed collectors are low in cost and don’t cause reflection (something which in glass–covered collectors often cause complaints).

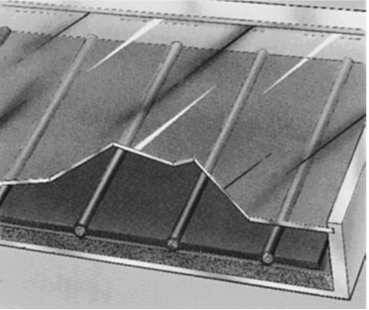

Glass-covered flat-plate collectors (illustration on the left): are the most widely used collectors. They are suitable for pre-heating water, for the production of hot water and for space heating. They are a somewhat more expensive than uncovered collectors. Thanks to their good thermal insulation they are suitable for integration in facades.

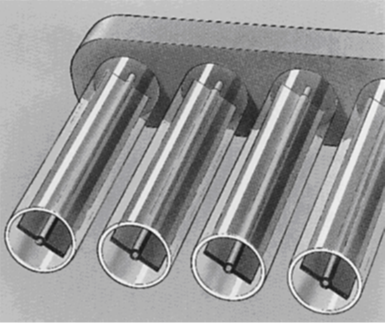

(Vacuum) tube collectors (illustration on the right): are especially ideal for the production of hot water or where external temperatures are generally low (or when a considerable part of solar irradiation takes place in winter). This is based on the idea that the absorber in a vacuum tube only loses energy for thermal radiation. In addition, the reflective behaviour of light and the geometry of the tube in glass contributes to making the obliquely falling light arrive more efficiently to the absorber compared to what happens in flat-plate collectors. Overall, tube collectors are the most expensive though, and for certain uses are not always as suitable as flat-plate collectors.

Solar Thermal Collectors

Together with thermal properties, geometric and optical properties also contribute to establishing the efficiency of collectors. On one hand, in the presence of low angles of incidence (when the surface of the collector is irradiated “obliquely”) the irradiated surfaces become smaller. On the other hand, the cover glass reflects light much more intensely the lower the angle of reflection. This property dependent on angle is called IAM (Incident Angle Modifier).

It is possible that the efficiency curve of a collector can be higher than that of another which due to its reflective properties shows a lower annual yield. As a consequence the IAM is equally important for the description of a collector as well as its efficiency.

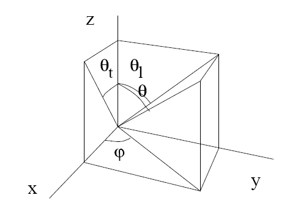

In a flat-plate collector, depending on size, it is of little importance that the angle is traced on the longitudinal axis or the transversal axis (longitudinally or transversally), as long as the glass does not have an unusual structure or the collector is not too elongated in shape.

The physical phenomenon of reflection and partial shade is well understood. It can be described by means of the Ambrosetti function \(K(\theta) = \ \ 1 – {(\tan{(\frac{\theta}{2}))}}^{a}\) with a single parameter. In respect to this reflectant properties are often defined at an angle of 50°. At this angle it is possible to experimentally define efficiency with great precision and evaluate the angular effect reasonably well. The IAM values between the longitudinal and transversal orientation are approximated with the function \(K(\theta,\varphi) = K\left( \theta_{l},0{^\circ} \right) \bullet {\cos(\varphi)}^{2} + K(\theta_{t},90{^\circ}) \bullet {\sin{(\varphi)}}^{2}\).

In tube collectors the two IAM values are different. Due to the reflective properties of the glass tube, in the transversal direction, the irradiation of energy diminishes less intensely in respect to what we should expect in the presence of the perspective reduction of the collector’s surface. Beginning at a certain point though, the IAM drops drastically, due to the reciprocal shadowing of the tubes.

The longitudinal direction can also be calculated by the Ambrosetti function and with a point of measurement at 50° inclination from the norm. For the transverse direction, given the geometry of the collector, more measurement points are necessary and are interpolated with the help of a cubic spline. The conditions for the scope of the spline, (first and second derivation), are correspondent to a reflection on the axis Z θ=0°. All of the values between the longitudinal axis and transversal axis are approximated by the well-known McIntire function. However, there is also the possiblity to insert IAM tables obtained by measurement or simulation.