Pipes and Heat Transfer Media

Pipes

The pipes are the links between the various components of the solar energy system. Their role is primarily to transport the heat transfer fluid among these components with a minimum of heat loss. Thin pipes have the advantage of having low volume, requiring little fluid and the heated fluid is rapidly transferred from the collector to the tank. On the other hand they also cause great pressure loss, compared to pipes with a greater diameter, which causes an elevated power absorption by the circulation pump. In Polysun it is possible to separately define inlet and return pipes. It is therefore possible, to better insulate the (hotter) inlet or size the return pipes thicker to reduce the pressure loss.

To define the thickness of the pipes the following aspects are to be considered:

- Pipes with a large diameter have a large surface area and therefore greater heat loss

- Pipes with a large internal diameter allow for a higher flow rate

- In thicker pipes the fluid flow is laminar, something which slows the transverse heat transfer in the fluid and causes lower heat losses

- Thicker pipes (equal in length) have a greater volume, which presupposes a greater quantity of heat transfer fluid in the collector loop and makes the system inert.

In light of these considerations it can be deduced that the diameter of the pipe needs to be rather small and is substantially established by means of the criteria of suitable pressure loss.

The diameter and thickness of the pipe walls are given by means of a catalog of commercially used pipes (copper and steel). In copper pipes the specification 22 x 1 indicates an external diameter of 22 mm and a wall thickness of 1 mm. In gas pipes the internal diameter is indicated in inches (1 inch = 2.54 cm).

Thermal Insulation of Pipes

The thermal insulation of piping is very important. During the transfer of heat to the tank one doesn’t want to lose the level of collector efficiency attained with much effort. With the use of thermal insulation with some centimeters of thickness acceptable heat losses can be sustained.

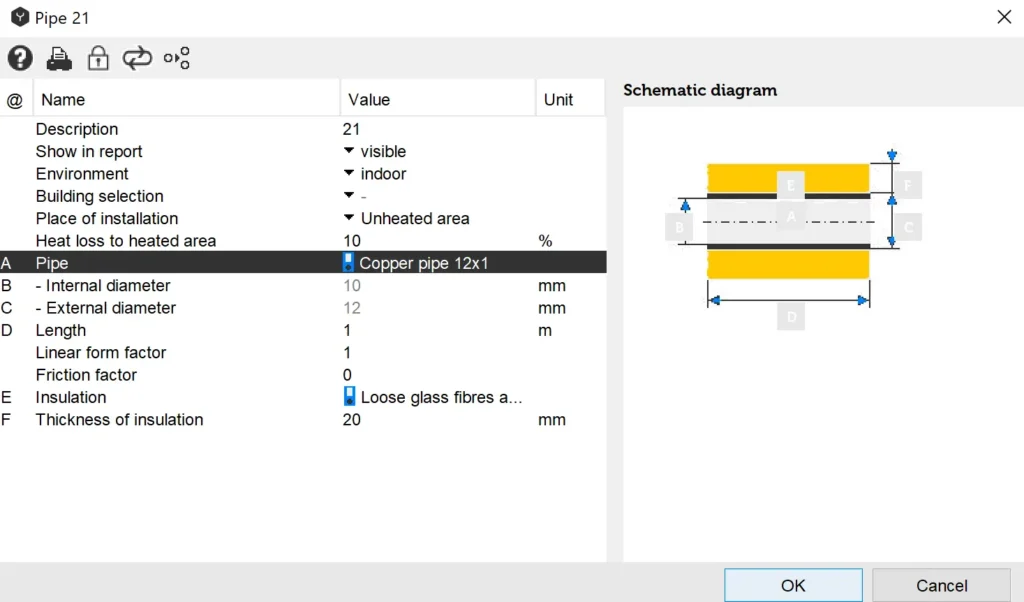

The connecting pipes are to be insulated as much as possible starting from the collector outflow. The thickness of the insulation can be regulated by the following dialogue (double click on pipe):

The thickness of thermal insulation can be freely defined, as well as the relative thermal conductivity. Likewise determinant for the efficiency of the piping is the conductivity and the heat capacity of the used metal pipes. The total length of the piping can be indicated separately in the respective fields. In the simulation it is important to also consider details such as the length of indoor piping, in respect to the length of outdoor piping. In this regard two separate pipes are established (at the Designer level) where the insulation thickness and length can be inserted separately.

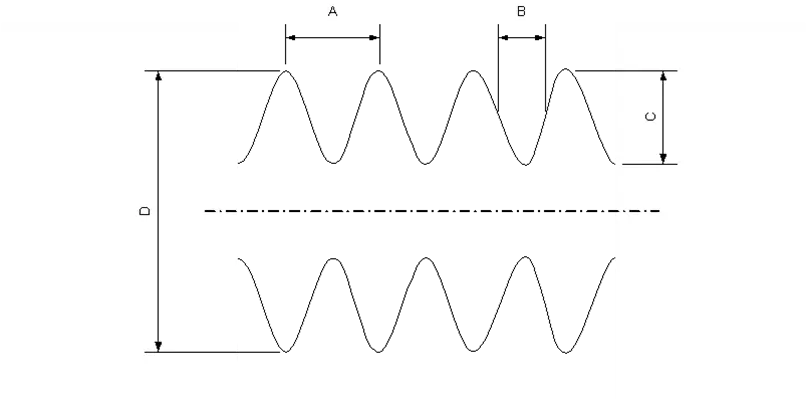

Pipe Dimensions

Heat Transfer Fluids

The climatic conditions in central Europe make it necessary for solar energy systems to be resistant to temperatures below zero. This, for example, impedes the production of necessary hot water directly in the collector. When water freezes inside the collector, it destroys the collector by means of its expansion. The water of the hydro network furthermore has the disadvantage that it tends to calcify the collector over time.

In order for the heat transfer fluid to be suitable for the above-mentioned needs, water is mixed with a certain quantity of glycol. In many cases ethylene glycol is used as an anti-freeze (for example Antifrogen L) or propylene glycol (e.g. Antifrogen N). From the moment the fluid circulates in a closed circuit, the danger of calcification is contained. For the mixing proportions the following various points of view are to be considered:

- The heat capacity of the fluid diminishes with an increased concentration of glycol

- Viscosity increases with higher percentages of glycol (problems with pressure loss)

- The freezing point drops with an increase in the percentage of glycol

- The boiling point increases with higher percentages of glycol

- Different possible chemical processes must be kept in mind, especially in passing through different metals

- The heat resistance of the fluid is to be considered

Freezing fluid is no longer a problem starting from a certain concentration as it no longer freezes as ice (crystalline), but rather in a grainy gelatinous form. Explosive effects are no longer evident. Beginning with a volumetric percentage of 33% (propylene glycol), or 38% (ethylene glycol), the fore-mentioned results take effect.

In Polysun the concentration of glycol can be defined. The corresponding physical properties for a temperature of 50°C are indicated.

Heat Transfer Media (Mix of Fluids)

- Danger of freezing in winter: if we consider that the external temperature can reach below zero, an anti-freeze product would be used (normally glycol). The higher the quantity of glycol, the lower the thermal capacity of the fluid. Ethylene glycol is normally used at a concentration of 33% (propylene glycol at 38%). In this way the fluid only freezes “like gelatin” without causing explosive effects inside the collector.

- Calcification of the system: for this condition there are two aspects to consider: if pipes with a small internal diameter are used inside the collector, calcification may obstruct the collector over time. Calcification may become a problem also in the tank. The situation is further aggravated if water is brought to temperatures above 60°C.

- Sterility of the tank: if domestic hot water is ready for use in the tank, there is a possible risk of legionella bacteria. This can be avoided by periodically heating the tank to above 65°C. In domestic hot water systems with an annual degree of coverage above 50%, sterility in summer is guaranteed by the temperature of the season.

For the choice of the system, cost considerations naturally also come into play. External heat exchangers are normally more expensive than internal ones, they require an auxiliary pump, but have greater transfer efficiency than internal heat exchangers. External heat exchangers are used above all in large systems, where the higher expense is compensated by greater efficiency.