Boilers

In most cases, solar energy systems are used as support to conventional systems for the heating of hot water. During the summer auxiliary heating is most often inactive, while during the winter it forms the main contribution to heating.

Electric auxiliary heating is often used to lighten the work load of the boiler in summer. Normally, by installing a solar energy system, the use of auxiliary electric heating is canceled. As electrical energy is more expensive compared to oil or gas, the use of night-time electrical power, which is the most economical, can be convenient (this can be defined in the detailed dialogue of the controller). In Polysun, auxiliary electrical heating is carried out as an internal element of the tank, while gas or oil auxiliary heating is in the form of a separate component.

The design of auxiliary heating, that is the height at which the inlet and the return are installed, where the temperature sensors are placed and at which temperature the heating is activated or turned off, plays an important part in the efficiency of a solar power system. If for example in the afternoon solar energy will be produced, there is no need to keep the boiler on until noon. In real systems, but also in the simulation of Polysun, it is possible to establish the precise times at which auxiliary heating (in case of need) comes into operation. The auxiliary heating is programmed on the basis of the orientation of the collectors. It makes sense to introduce auxiliary heating only if after the irradiation of the collector, the level of required heat has not been reached in the tank. According to the consumption profile it could also be useful, directly before a peak in use, to make available the quantity of necessary heat in conditions when the sun hasn’t provided sufficient energy. This way the tank losses are reduced to the minimum and a good possibility to find favourable working conditions (low tank temperatures) is given to the sun.

In Polysun, as in real heating systems, it is possible to define the operating times. Controllers are used for this purpose (see below).

The quantity of heated energy is defined as the product of the “heated volume” multiplied by the difference in temperature of hot and cold water (multiplied by the capacity of the fluid). The volume is given from the contents of the entire tank and the layer in which the electrical immersion heater and the temperature sensors are found.

In defining the project, on the page “Consumer”, the daily energy consumption (“Hot water: daily demand”) is indicated. If you want to be sure that the supply of hot water is guaranteed in unfavourable conditions, you have to make certain that, as in the example, the quantity of heated energy and daily use are approximately equal. In most cases you can choose lower quantities of heated energy (for example electrical immersion heater in layer 10). This way the sun is given greater possibility to supply the necessary energy during the day.

The control of auxiliary heating can be carried out by means of two temperature sensors, which can be freely placed above the electrical immersion heater. It is possible to choose the on/off temperature in different ways, but the switch-on temperature must be lower than the switch-off temperature. The desired hot water temperature adopted in the example is 50°C. The switch-off temperature should always be a few degrees above this so that even after a few hours the tank temperature doesn’t drop too much. Finally, electrical energy is used only if an external temperature of at least 17°C is registered (i.e. in summer). This way great losses from the boiler are avoided for brief periods of operation.

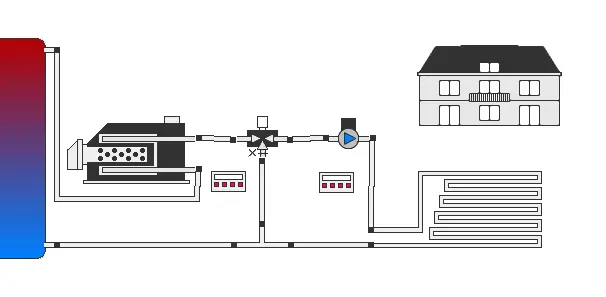

Another frequent disposition is the use of a boiler for a temperature increase in the return

(return shunt). In the case where a non modulating boiler is utilized, one must make sure that the boiler volume is large enough so that the fluid in the boiler doesn’t overheat (Polysun would at this point choose a very short time step, which would influence negatively on the simulation times).

Fuel and CO2 Savings

The use of the solar energy system enables to reduce both fuel demand and CO2 emissions. Polysun calculates savings based on a calorific value table and the annual average efficiency of the heat generator. Double-clicking the heat generator and subsequently on the “Fuel” folder you will enter the fuel catalog. The catalog provides the user with a wide selection of fuels, stating the heating value and the CO2 emissions of each fuel. A selection of fuels is already available, the user can create user-defined entries as required.

Fuel and CO2 savings may be found under “Boiler” in the “Components results”. The values are calculated according to the following formulas:

\({CO}_{2}\ savings\ solar\ thermal = energy\ savings\ solar\ thermal*{CO}_{2}\ emissions\ of\ fuel\)

\(Fuel\ savings\ solar\ thermal = \frac{energy\ savings\ solar\ thermal}{heating\ value\ of\ fuel}\)

\(Energy\ savings\ solar\ thermal = fuel\ savings\ solar\ thermal*heating\ value\ of\ fuel\ \)

\(Energy\ savings\ solar\ thermal = \frac{Qsol}{Nominal\ efficiency\ of\ boiler}\)

The data included in the fuel catalog (CO2 emissions and heating values) come from the ecoinvent centre (Schweizer Zentrum für Ökoinventare).